Case Study: Flexible Kitchen Ventilation System

High-End Design That Delivers Flexibility: Inside Zink's Culinary Center

Discover how Z-Ventilation Solutions transforms commercial kitchens with our industry-leading ventilation systems.

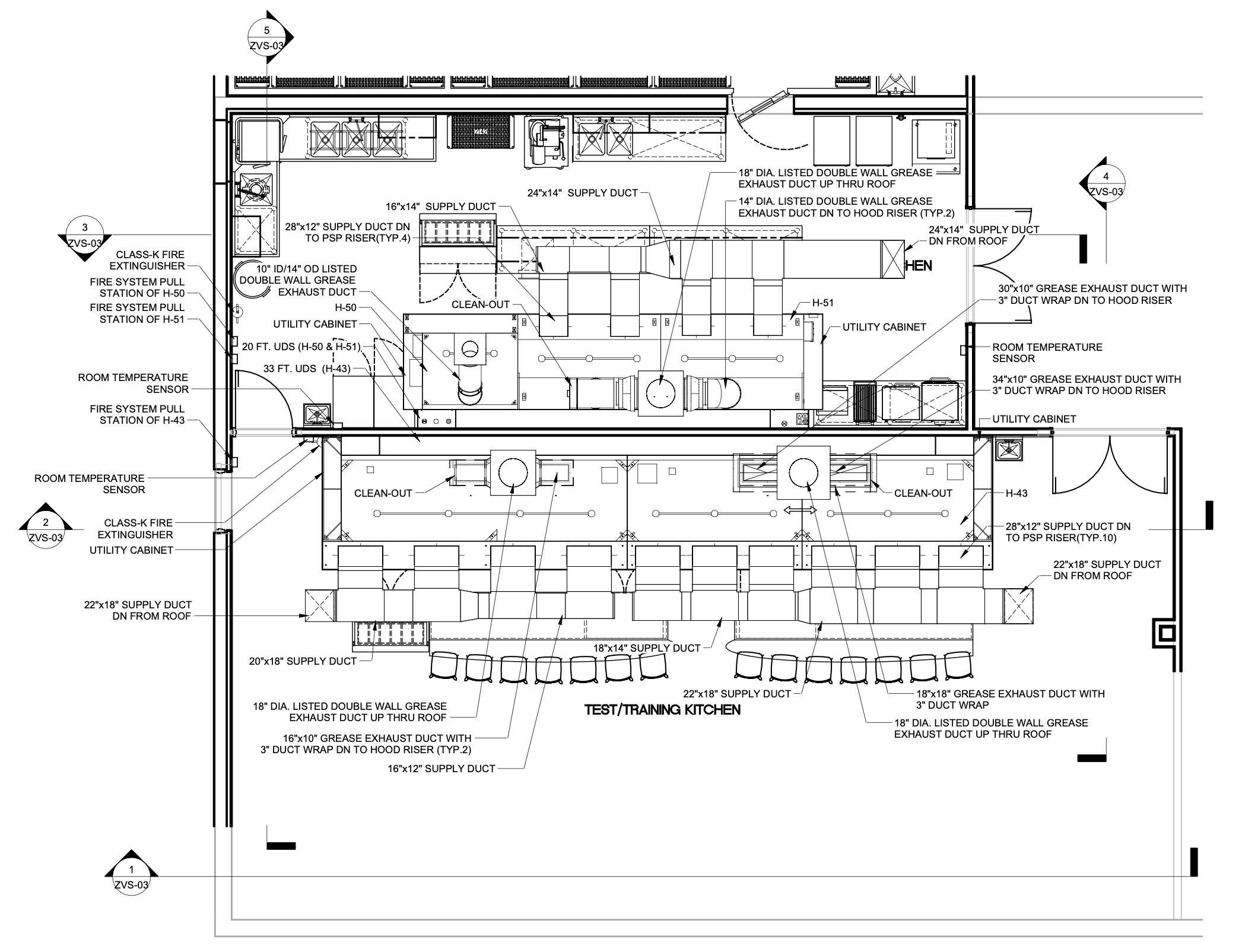

Site Survey

Evaluate and measure your building with detailed dimensions ensuring no surprises prior to engineering your system.

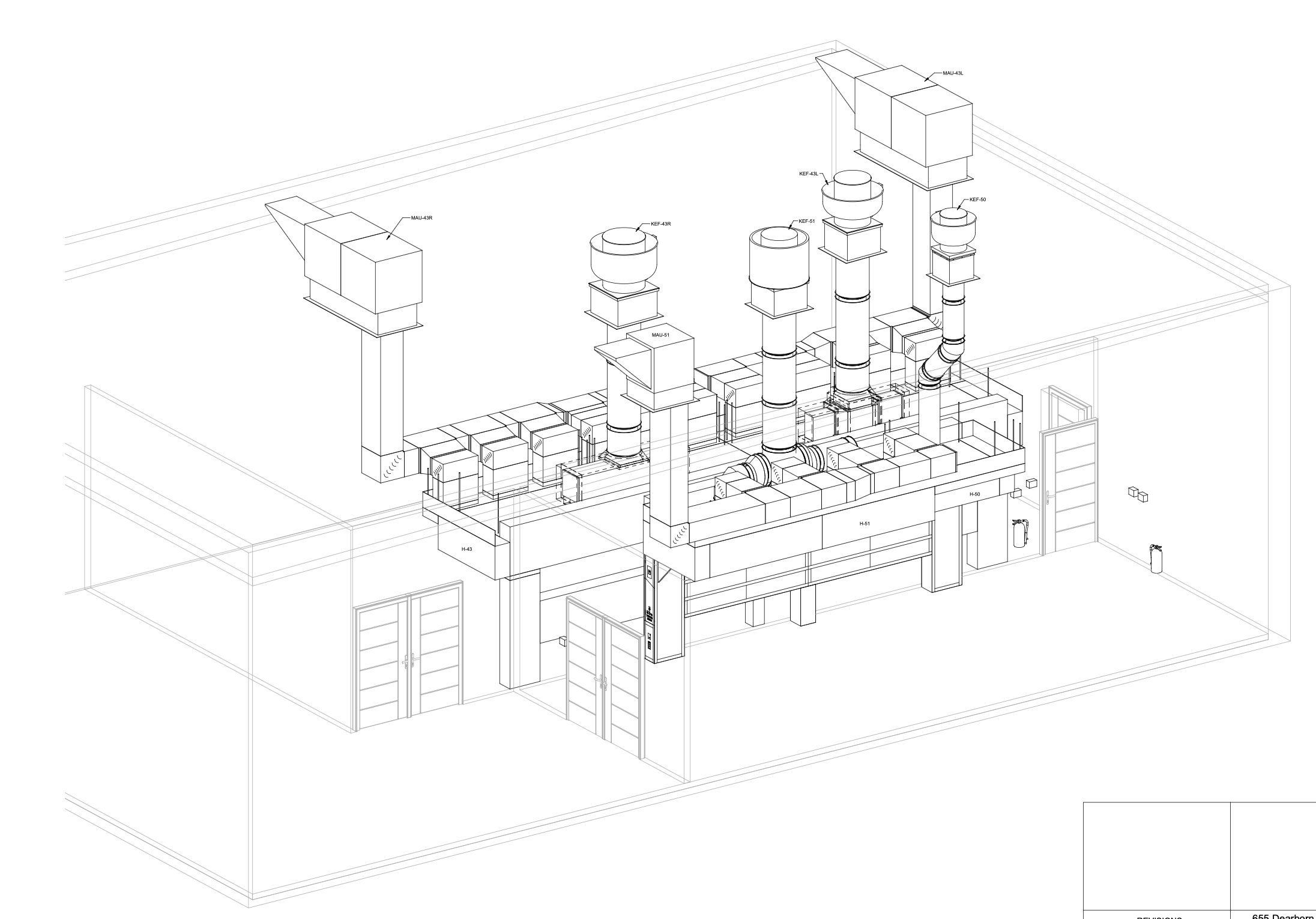

Design & Engineering

Tailored ventilation systems designed to meet the unique requirements of your kitchen.

Package Quote & Expert Installation

Our team ensures seamless integration and installation of entire ventilation system.

Final Startup & Testing

Factory Certified Technician will inspect the installation of the hood system

About Z-Ventilation Solutions

Z-Ventilation Solutions (ZVS) is a leader in providing turnkey, customized solutions for commercial kitchen ventilation systems. Our expertise spans across restaurants, hospitals, and institutional cafeterias. What sets us apart is our comprehensive approach, combining design, engineering, sales, and installation to deliver unparalleled service. Our mission is to offer End-to-End Solutions that ensure optimal performance, safety, and compliance for every project.

Zink Columbus Culinary Center Project

Training Facility

Client

Zink Foodservice

Date

November 2024

Ventilation Package

Key Installation Features

Our project at Zink’s Culinary Center showcases several key elements that highlight our expertise and commitment to quality. From utility upgrades to advanced installation techniques, we ensured every aspect of the kitchen ventilation system was optimized for performance and safety.

Flexibility for Routine Equipment Changes

With full fire suppression coverage every 12 inches, adjustable Geo-Vary baffle filters, and UDS utility access. This allows equipment to be moved, swapped, or reconfigured without compromising safety, capture, or airflow—ideal for kitchens that train, test, or frequently update their lineup.

Energy Efficiency Through Smart, Automated Controls

The Z-Tech demand-control system paired with the ZZ-200 Series Control Panel, continuously modulates fan speed based on actual cooking load. This reduces energy consumption, limits wasted airflow, and removes the need for manual VFD adjustments on the roof—delivering consistent performance with lower operating costs.

Quiet, Comfortable Kitchen Operation

Pre-engineered insulated ductwork, only when needed airflow from the Z-Tech system, and properly sized fans allow the space to operate at significantly reduced noise levels. The result is a quieter, more comfortable environment where chefs can train, communicate, and host demonstrations without the distraction of unnecessary fan noise.

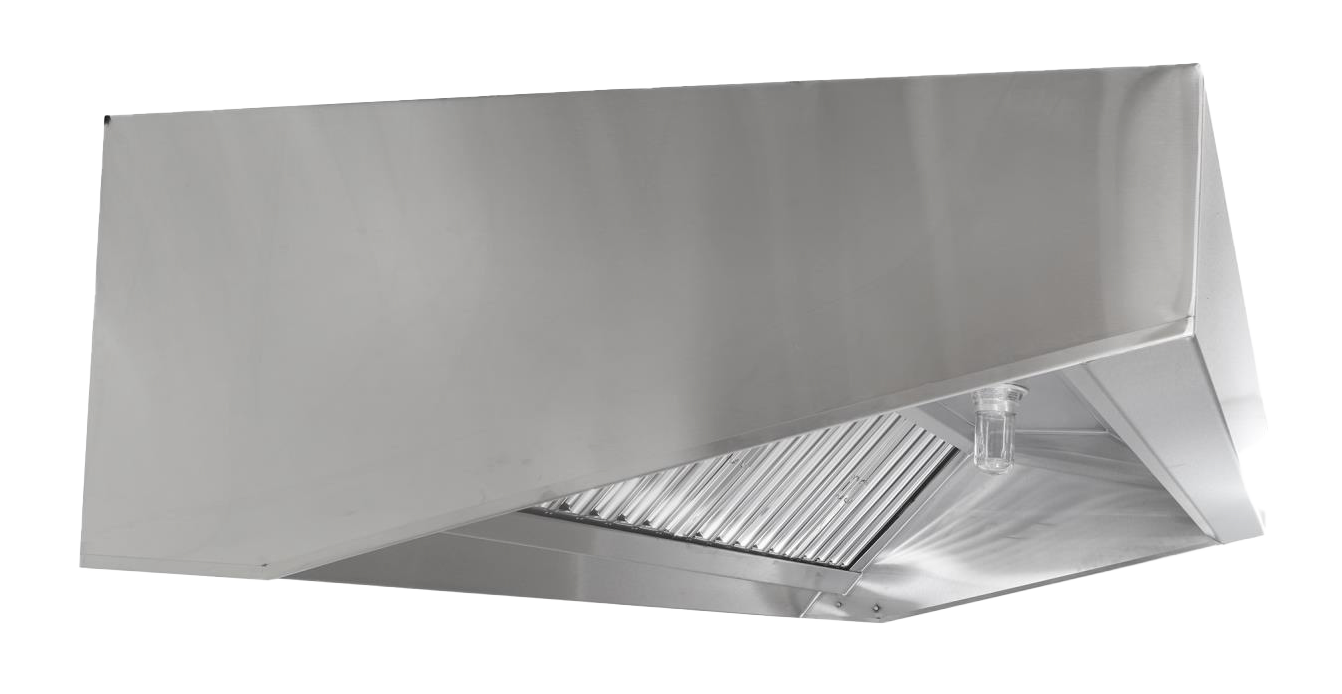

Training Center Flexible Hood Package

The heart of the facility features ZA Series hoods spanning 33 feet, equipped with Z-Tech demand-control technology and the ZZ-200 Series Control Panel with integrated LED lighting.

Z-Tech Demand Control Ventilation

Adjusts exhaust and supply air automatically based on cooking load, reducing energy use while keeping the kitchen comfortable.

Geo-Vary Baffle Filters

These adjustable filters rotate air repeatedly, ensuring grease separates and falls into the troughs instead of traveling up the duct.

ZZ-200 Control Panel

Operators can control every exhaust and supply function from a single point—with no ladders, no climbing on the roof, and no manual adjustments to the VFD. This centralized control improves efficiency and simplifies daily operation.

Flexibility with Fire Suppression Every 12 Inches

Full hood-line coverage gives the culinary team the freedom to rearrange equipment without compromising safety—ideal for constant training, demos, and menu testing in a dynamic space.

The Prep Kitchen Hood Package for Power, Safety, and Versatility

To support cooking, operator trainings, and multi-equipment demos, the prep kitchen is engineered for maximum horsepower and versatility.

-

15 feet of hood coverage

-

330 AMP electrical service

-

1 million BTUs of gas

-

Full water utilities through a Utility Distribution Cabinet (UDS)

In short: plug in anything, cook anything, and rearrange anything.

This space includes a 15′ Ohio-approved S.M.A.R.T. Hood system. Instead of tempering makeup air elsewhere in the building, non-tempered air is brought directly into the hood and exhausted immediately—a smart, efficient choice for a high-use prep environment.

The ZVS End-to-End Approach

Why This Project Matters

The Zink Columbus Culinary Center is more than a showroom or training environment—it’s a working demonstration of what Industry Established Ventilation Experts can design, build, and engineer. ZVS applied its full End-to-End approach:

-

Professional Engineering Guidance from concept to final commissioning

-

Customized hood packages tailored to each kitchen area

-

Facility-wide ductwork manufactured for durability

-

Systems built to allow constant equipment movement and testing

-

Energy-efficient controls that support long-term operational savings

For operators, chefs, architects, and designers visiting the space, this installation is a proof point: ZVS builds ventilation packages that perform at the highest level while remaining flexible enough to grow and adapt with your kitchen.

Ready to Bring High-End, Flexible Ventilation Design to Your Facility?

Reach out to Z-Ventilation Solutions for an end-to-end solution tailored to your needs. Our team of industry-established ventilation experts is here to provide you with professional engineering guidance and customized top-of-the-line hood packages. Contact us now to learn how we can help you achieve optimal performance and compliance with our comprehensive solutions.